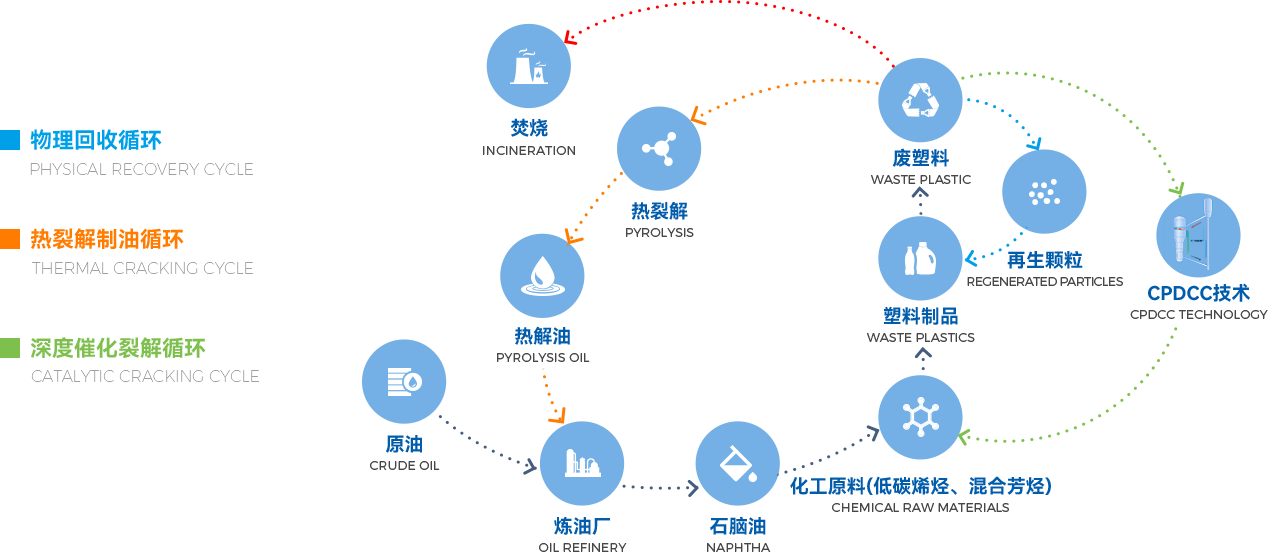

混合废塑料化学循环

Huicheng's original and innovative deep catalytic cracking technology for waste plastics,

We have successfully overcome the key technical challenges in the chemical recycling and reuse of waste plastics, achieving a revolutionary "one-step" process,

It can achieve high-value recycling of low-value waste plastics, eliminating white pollution;

It also holds high strategic significance in reducing China's dependence on foreign crude oil, decreasing carbon dioxide emissions, and empowering the implementation of the dual-carbon strategy,

It provides a revolutionary "Chinese solution" for global plastic pollution control!

The company's proprietary Catalytic Pyrolysis of Composite Plastic Waste (CPDCC) technology directly converts various types of low-value waste plastics into products such as Liquefied Plastic Cracking Gas (LPCG), Plastic Cracking Gas (PCG), and Plastic Cracking Light Oil (PCLO) in a "one-step process", achieving a yield exceeding 92%. This technology has overcome industry bottlenecks such as the difficulty of sorting waste plastics, low yields of target products, poor product quality, and the corrosive nature of hydrogen chloride. The overall process technology is a world first.

● Continuous and stable feeding is achieved through gas-solid two-phase differential pressure conveying technology, enabling the successful scaling up and large-scale implementation of industrial plants.

The contradiction between the cracking depth of liquid-phase macromolecular hydrocarbons and high-temperature carbonization in the traditional plastic chemical recycling process has been overcome through cross-phase cracking.

● The original design of a countercurrent bed reactor is adopted, providing a matched reaction activation energy for hydrocarbon cracking with different molecular weight gradients based on the reactor temperature gradient.

● Cross-phase deep cracking and high-temperature chlorine capture have overcome the challenge of hydrogen chloride corrosion resulting from PVC cracking.

东粤化学20万吨/年混合废塑料资源化综合利用示范性项目

广东东粤化学科技有限公司成立于2023年,是青岛惠城环保科技集团股份有限公司旗下子公司,坐落于蓬勃发展的石化新区——广东省揭阳市大南海石化工业区,注册资本5.8亿元,拥有210余亩工业园区。东粤化学秉承“原始技术创新 向废物要资源”的发展理念,建设20万吨/年混合废塑料资源化综合利用示范性项目,致力于废塑料化学回收与循环利用,推动有限资源的无限循环。

20万吨/年混合废塑料资源化综合利用示范性项目,是揭阳市“百千万工程”的标杆项目,是大南海石化工业区“一超多强”绿色石化产业格局中的重点特色产业链主项目,也是落实“聚焦延链补链强链,做大做强绿色石化”重要指示精神的具体举措。项目总投资15.08亿元,于2025年正式投产。项目在国际上开创性地采用混合废塑料深度催化裂解技术(CPDCC),直接将混合废塑料裂解为高附加值化工原料,是我国在塑料化学循环行业核心技术自主创新道路上取得的一次重大突破,为破解全球塑料污染困局、构建资源循环体系提供了极具示范价值的中国方案,具备显著的环境效益与经济效益。

随着20万吨/年示范项目的产业化落地,惠城将长远谋划百万吨级绿色循环产业基地,与高端新材料企业构筑“废塑料→循环化工原料→循环高端材料”的全产业链,推动形成千亿级绿色化工新材料产业集群,让“废塑料变资源”的绿色循环产业模式实现全国布局,并走向世界。