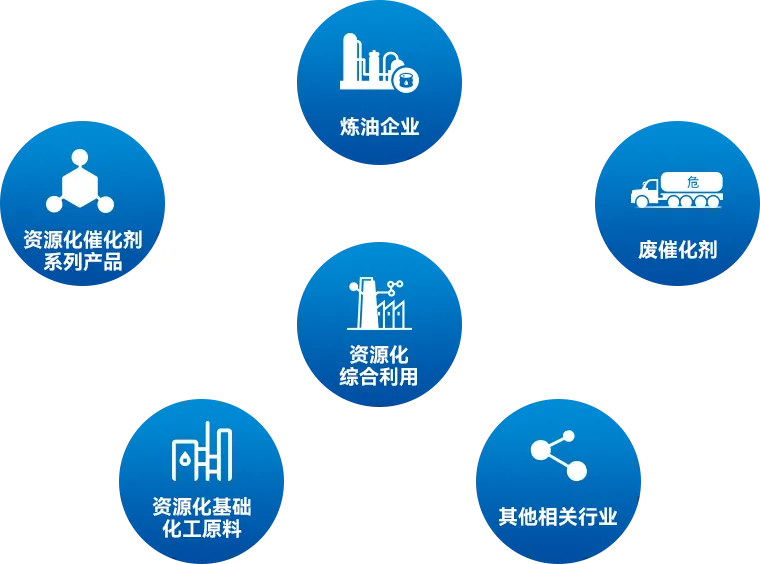

The company holds a hazardous waste operation license issued by the local provincial environmental protection department, with hazardous waste categories: HW50,251-017-50. Currently, its hazardous waste disposal capacity is nearly 60,000 tons per year. It mainly provides FCC waste catalyst treatment and disposal services for oil refining enterprises. The company has created its own business model of "waste catalyst treatment and disposal + waste catalyst resource recovery production and reuse + resource recovery catalyst sales", which completely solves customers' worries about waste catalyst treatment. It has formed a virtuous cycle of mutual promotion between "waste catalyst disposal and catalyst sales". Currently, it has become one of the few domestic enterprises with the ability to provide customers with a fully integrated resource recovery cycle model of professional customized catalyst products and waste catalyst treatment and disposal.

This equipment adopts a fully automatic electromagnetic process that integrates vacuum feeding, material storage, feeding, magnetic separation, iron removal, cooling, and control. It can reduce heavy metals by more than 30%. The resulting low-magnetic agent product is mainly used for startup of catalytic cracking units, catalyst loss, and replacement of catalyst heavy metal poisoning.

We possess one set each of fixed and mobile magnetic separation equipment. The mobile magnetic separation equipment can be transported to the customer's site for magnetic separation. The low-magnetic agent after magnetic separation is returned to the device as a high-quality balancing agent, achieving the functions of replacing metals, ensuring the activity of the catalytic system, and reducing the consumption of fresh agent.

The inventory of low-magnetic agents is always maintained at over 5,000 tons, which can meet the different needs of customers. The company's transportation is fast and efficient, with delivery within 8 hours for distances within 500 kilometers and within 24 hours for distances within 1,000 kilometers, ensuring the normal production needs of customers.

移动式磁分离设备

移动式磁分离设备

固定式磁分离设备

固定式磁分离设备

Huicheng Environmental Protection's proprietary resource utilization technology: It processes spent catalysts and flue gas desulfurization sludge that cannot be revived by catalytic cracking units, separating and purifying elements such as Si, Al, Re, Ni, and V contained therein, to obtain silicon, aluminum, rare earths, nickel, vanadium, and other related products that can be reused in other industries. The resource utilization technology for catalytic cracking hazardous waste not only provides a comprehensive disposal solution for zero emissions from catalytic cracking units but also extends the sustainable development of related industries.