The Catalytic Cracking Service Center boasts an experienced team of refining experts, possessing both basic and applied research capabilities in catalytic cracking technology. Through regular on-site technical exchanges, the expert team conducts in-depth collection of customer device parameters, catalyst usage, and raw material property data. Combining years of refining experience, they provide customers with device operation optimization solutions. Additionally, the team can assist in providing full-cycle technical service support for the startup and shutdown of catalytic cracking units.

- 精确化数据分析

- 创新性远程诊断

- 专家级现场服务

Analysis of catalytic feedstock oil properties

Analysis of catalytic feedstock oil properties

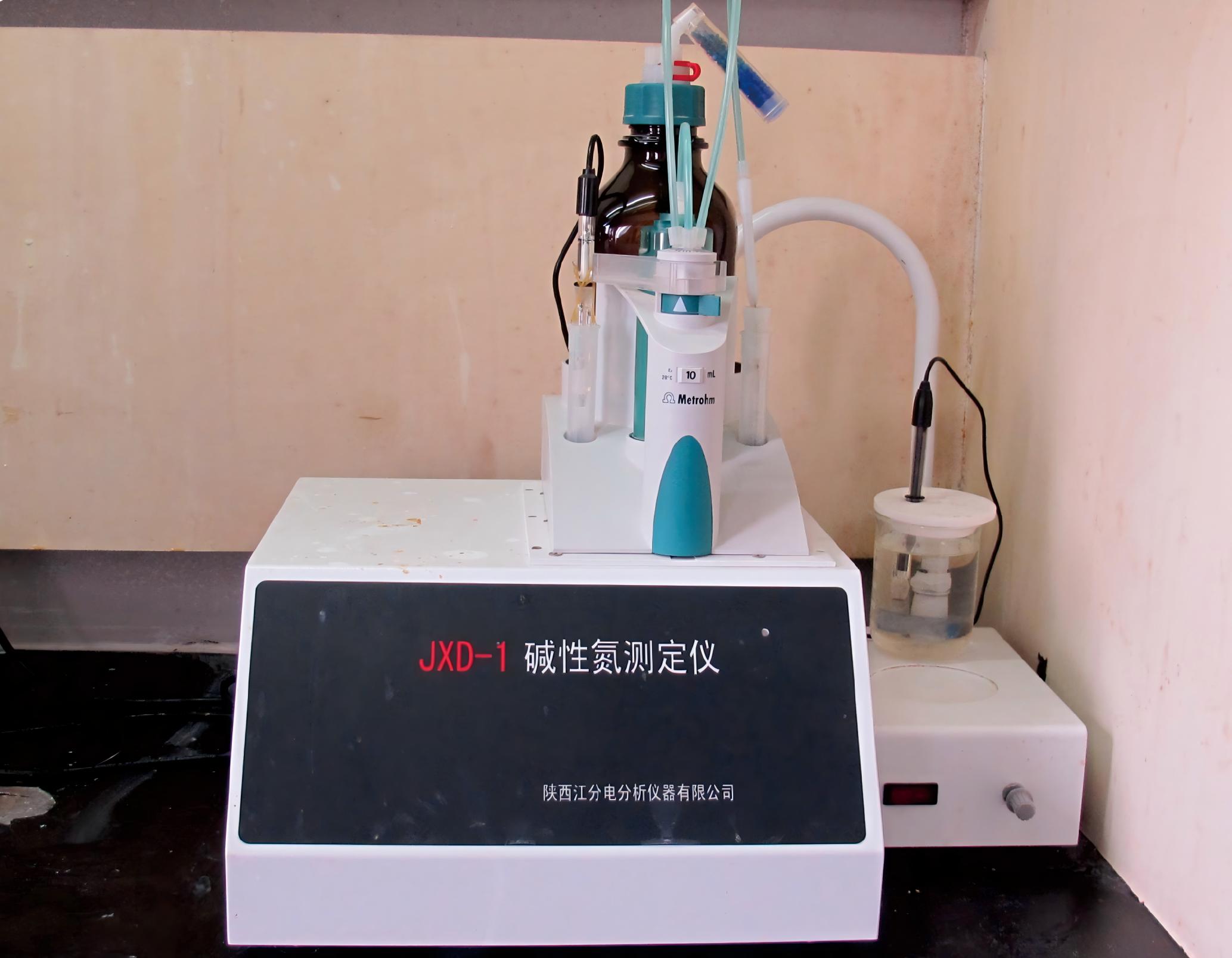

General property analysis: density, distillation range, carbon residue, basic nitrogen

Composition analysis: saturated hydrocarbons, aromatic hydrocarbons, asphaltenes, and resins

Metal content analysis: Fe, Ni, V, Ca, Na

Analysis of physicochemical indicators of catalyst

Analysis of physicochemical indicators of catalyst

Micro-reactor activity, specific surface area, chemical composition, wear, particle size distribution, crystallinity, bulk density, ignition loss, hydrothermal stability, pore volume, fixed carbon

Sampling analysis of thermal calibration of catalytic cracking three-stage cyclone separation performance

Sampling analysis of thermal calibration of catalytic cracking three-stage cyclone separation performance

Special sampling equipment is used to measure the dust (catalyst) concentration at the inlet and outlet of the third cyclone of the catalytic cracking unit, to assess the operating condition and separation efficiency of the third cyclone equipment, and to provide data support for protecting the flue gas turbine. In addition, Huicheng Environmental Protection also provides customers with testing services for the content of SO2, NOX, etc. in flue gas, providing data support for process adjustments.

Equipped with a small spray sampling system, a heavy oil catalytic cracking micro-reactor, a fixed fluidized bed experimental device, an American ACE evaluation experimental device, and a medium-sized adiabatic riser catalytic cracking experimental device, it forms a four-level catalyst evaluation system, capable of accurately providing customers with raw oil and catalyst effect evaluations, flexibly adjusting catalyst integration schemes, and ensuring maximum customer benefits.

Preferred catalyst

• Collect raw oil from users for physicochemical index analysis

• Collect user device parameters

catalyst evaluation

• Collect raw oil from users for physicochemical index analysis

• Collect user device parameters

Develop catalyst formula

• Collect raw oil from users for physicochemical index analysis

• Collect user device parameters

Collect user samples

• Collect raw oil from users for physicochemical index analysis

• Collect user device parameters

X射线荧光光谱仪_副本_20251204171930A016.png)